A symbol of resilience, peace, solidarity and unity. The “horse” that rode through Paris on the occasion of the opening ceremony embodies the values at the heart of the partnership between PowerTech Systems, Atelier BLAM, MM Process, Transfluid and Paris 2024.

As well as being a powerful symbol, Zeus ride is also the result of the know-how and spirit of scientific and artistic innovation of a group of French companies.

The prototype is powered by a 130kW 384V motor, assembled inside the hull.

In addition to this, the central hull contains most of the electrical components, including energy storage:

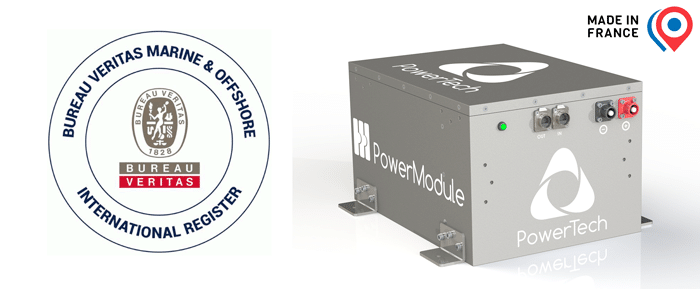

-16 x PowerModule 48V (86kWh) propulsion batteries, batteries certified by Bureau Veritas ESTRIN

-1 x PowerBrick 48V-105Ah battery for the horse mechanism (5.37kWh)

-1 x PowerBrick 24V-50Ah battery for control and lighting (1.2kWh).

Zeus ride is a true technical challenge and a scene forever engraved in the eyes of the whole world. This is undoubtedly one of the most memorable creations of the Olympic Games Opening Ceremony.

France

France Europe

Europe Rest of the world

Rest of the world