The revolution of solid-state batteries

The lithium-ion battery sector is constantly evolving, with daily research aimed at improving battery performance, range, power and charge times.

Among recent technologies, solid-state batteries represent a major development for the future of electric mobility.

These batteries use a solid electrolyte instead of the liquid electrolyte of traditional lithium-ion batteries.

1. Operating principle of Standard LFP vs Solid-State LFP batteries

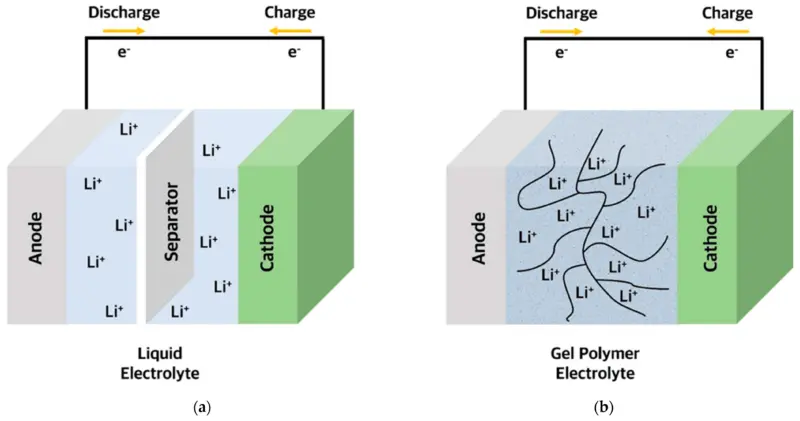

- LiFePo4 / LFP batteries: These consist of two electrodes (cathode and anode) separated by a liquid electrolyte. Lithium-ion moves between the electrodes during charging and discharging.

- Solid-state LiFePo4 / LFP batteries: Replace the liquid electrolyte with a solid electrolyte (ceramic or polymer), and use a pure lithium metal anode. This design eliminates the graphite structure of the anode, thus increasing energy density.

the video below details the operating principles of a solid-state lithium battery.

2. Advantages of solid-state batteries

- Increased safety: The absence of flammable liquid electrolyte makes these batteries less prone to short-circuits and the formation of dendrites (lithium build-up) that can damage lithium-ion batteries.

- Very low internal resistance : The design of the solid-state electrode results in an internal resistance 2 to 3 times lower than that of a conventional lithium battery.

As a result, battery cells heat up much less during use. The benefits are direct: batteries that don’t heat up much during use degrade much less quickly

For example, our laboratory tests show that when discharged at 3C (20 minutes to fully discharge the LFP Solid State battery), the battery heats up by only 23°C, which is 1/3 of the temperature rise seen on a standard LFP battery.

This resistance to overheating means that power batteries can be designed without the need for internal cell cooling. - Ultra-fast charging : Solid-state batteries can be charged up to four times faster than conventional lithium-ion batteries.

What’s more, they are more resistant to heat, which improves their performance during rapid charging. - Longer service life: Solid-state batteries tend to have a longer service life due to the reduced chemical degradation of solid electrolytes compared with liquid electrolytes.

More specifically, the low temperature rise during use means that cells can be kept at temperatures compatible with a long service life.

As a result, they can withstand more charge-discharge cycles before their capacity degrades significantly. - Higher energy density: In the future, lithium metal in the anode will enable higher energy density than current lithium-ion batteries, resulting in a lighter, more compact battery with greater autonomy.

3. Semi-Solid batteries, roadmap and prospects

Solid-state batteries hold great promise, particularly in terms of safety, performance and durability.

But we’ll have to wait a few more years to achieve large-scale, cost-effective production.

The technological stakes are such that a number of steps still need to be taken, particularly with regard to the durability of metallic or ceramic electrolytes.

While we wait for solid electrolytes to replace liquids, research is focusing on an intermediate technology: semi-solid batteries with polymerized electrolytes.

Polymerized electrolytes (also known as gel electrolytes) contain ionic conductors such as lithium salts, which enable much more efficient ionic conductivity. The polymer structure also resists the formation of dendrites, needle-like structures that can form on the anode during charging and cause short circuits. Gels are also much less volatile than liquid electrolytes, making them very difficult to ignite.

Although semi-solid-state batteries do not achieve the energy densities and lifetimes expected of solid-state batteries, they offer a medium-term advantage in that they can be manufactured on conventional lithium-ion battery production lines. Just as importantly, they have been tested and are now available on the market. On the other hand, Solid-state cells will be available at a reasonable cost by 2027-2028.

The energy density of semi-solid batteries is currently similar or slightly higher to that of standard LFP batteries, but all the other advantages of solid-state are already there. We can expect this lithium battery technology to gain momentum, with a major evolutionary step towards ever-increasing energy density in the years to come.

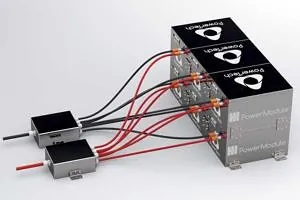

The future is already here: the new PowerModule SOLID-STATE product, equipped with semi-solid cells technology is already operational and available :

France

France Europe

Europe Rest of the world

Rest of the world