Subscribe to Newsletter

We will send you news from PowerTech Systems on a regular basis.

Maximum one email per month

Please fill-in right form with your contact details and click "Register"

Lead acid batteries are made from (not surprisingly) a mixture of lead plates and sulfuric acid. This was the first type of rechargeable battery, invented way back in 1859.

Lithium ion batteries on the other hand are a much newer invention, and have only been around in a commercially viable form since the 1980′s.

Lithium technology has become well proven and understood for powering small electronics like laptops or cordless tools, and has become increasingly common in these applications – edging out the older NiCad (Nickel-Cadmium) rechargeable battery chemistry due to lithium’s many advantages.

But as you might recall from the many news stories a few years ago around defective laptop batteries bursting into flame – lithium ion batteries also earned a reputation for catching fire in a very dramatic fashion.

The commonly used lithium ion battery formulation had been Lithium-Cobalt-Oxide (LiCoO2), and this battery chemistry is prone to thermal runaway if the battery is ever accidentally overcharged. This could lead to the battery setting itself on fire – and a lithium fire burns hot and fast.

This is one of the reasons that up until recently, LiCoO2 was rarely used to create large battery banks.

But in 1996 a new formula for mixing lithium ion batteries was developed – Lithium Iron Phosphate. Known as LiFePO4 or LFP, these batteries have a slightly lower energy density but are intrinsically non-combustable, and thus vastly safer than Lithium-Cobalt-Oxide. And once you consider the advantages, Lithium-Ion batteries becomes exceedingly tempting.

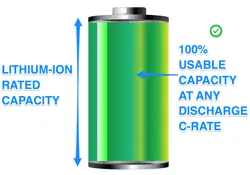

Unlike with lead acid batteries, it is considered practical to regularly use 90% or more of the rated capacity of a lithium battery bank, and occasionally more. Consider a 100 amp hour battery – if it was lead acid you would be wise to use just 30 to 50 amp hours of juice, but with lithium you could tap into 90 amp hours or even 100Ah (100% DoD).

|

|

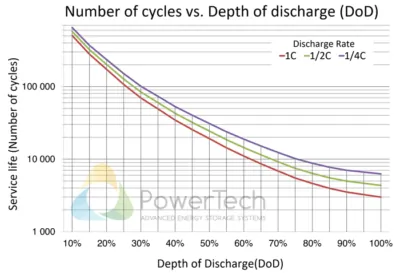

Manufacturers and laboratories report that tens of thousands of cycles can be expected from a high quality LiFePo4 battery. However, these are theoretical values that could not be easily verified.

From a practical point of view, and in real use, standard quality LiFePo4 batteries can deliver at least 2000 charge/discharge cycles at 80% DoD and 1C discharge rate, and the remaining capacity remains above 80%. These values are dependent on the charge rate, the depth of discharge but more importantly on the quality of the cells used.

These cycle life results are much more better than NMC or NCA chemistries, massively used in electric vehicle industry. In contrast, even the best deep cycle lead acid batteries are typically only good for 500-1000 cycles.

For batteries, such as those produced by PowerTech Systems, using high quality cells, sorted and matched, 4000 to 5000 cycles can be delivered at 1C and 80% DoD. This number of cycles can be greatly increased by reducing the depth of discharge (DoD).

The diagram below shows the number of cycles as a function of the depth of discharge for the PowerBrick , PowerRack and PowerModule product range :

The discharge curve of lithium batteries (especially relative to lead acid) is essentially flat – meaning that a 20% charged battery will be providing nearly the same output voltage as an 80% charged battery.

This prevents any issues caused by the “voltage sag” common to lead acid as they discharge, but does mean that any battery monitor or generator auto-start dependent upon voltage levels will likely not work well at all when monitoring a lithium bank.

Another huge advantage of lithium batteries is that Peukert’s losses are essentially non-existant. This means that Lithium-Ion batteries can deliver their full rated capacity, even at high currents. Whereas lead acid can see as much as a 40% loss of capacity at high loads.

In practice, this means that Lithium-Ion battery banks are very well suited to powering high current loads like an air conditioner, a microwave or an induction cooktop.

To highlight the unique characteristics in terms of weight and size of the lithium-ion batteries, let’s take a significant example : lead acid vs Lithium battery.

Lithium-ion batteries can be “fast” charged to 100% of capacity. Unlike with lead acid, there is no need for an absorption phase to get the final 20% stored. And, if your charger is powerful enough, these batteries can also be charged insanely fast. If you can provide enough charging amps – you can actually fully charge a lithium ion battery just 30 minutes.

But even if you don’t manage to fully top off to 100%, no worries – unlike with lead acid, a failure to regularly fully charge Lithium-Ion batteries does not damage the batteries.

This give you lots of flexibility to tap into energy sources whenever you can get them without worrying about needing to do a full charge regularly. Several partly cloudy days with your solar system? No problem that you can’t top off before the sun goes down, as long as you’re keeping on top of your needs. With lithium, you can charge up what you can and not fret about leaving your battery bank perpetually undercharged.

Lead acid batteries are less efficient at storing power than lithium ion batteries. The latter charge at nearly 100% efficiency, compared to the 85% efficiency of most lead acid batteries.

This can be especially important when charging via solar, when you are trying to squeeze as much efficiency out of every amp as possible before the sun goes down or gets covered up by clouds.

Theoretically, with lithium nearly every drop of sun you’re able to collect goes into your batteries. With limited roof & storage space for panels, this become very important in optimizing every square inch of wattage you’re able to mount.

Lead acid batteries and lithium lose their capacity in cold environments. As you can see in the diagram below, Lithium-ion batteries are much more efficient at low temperatures. Moreover, the discharge rate affects the performance of lead acid batteries. At -20°C, a Lithium battery that delivers a 1C current (one times its capacity), can deliver more than 80% of its energy when the AGM battery will deliver 30% of its capacity.

For harsh environments (hot and cold), Lithium-Ion is the technological choice.

Lithium-ion batteries do not need to be stored upright, or in a vented battery compartment. They can also fairly easily be assembled into odd shapes – an advantage if you are trying to squeeze as much power as possible into a small compartment.

This is especially useful if you have an existing battery bay that is limited in size, but you want or need more capacity than lead acid is currently able to provide.

Thee batteries are fairly maintenance free. A “balancing” process to make sure all the cells in a battery bank are equally charged is automatically achieved by the BMS (Battery Management System). Just charge you battery and you are good to go.